Technology has made significant advancements and has already solved many of the supply chain challenges affecting companies today. However, we can’t claim that all the challenges have decreased when compared to previous years.

On the contrary, globalisation, trade sanctions, Brexit, an eCommerce revolution and finally a global pandemic are just some of the factors that are complicating an overcomplicated supply chain – especially for companies that might lack the resources of bigger corporations.

Developments in AI have assisted in the planning and development of operations across the supply chain. And if the pandemic has taught us one thing, it is the importance of forward planning and anticipating supply chain challenges. Artificial intelligence can be used to evaluate risk and identify any possible pressure points across the chain.

Supply chain management has become increasingly difficult in recent years, as the physical flows are becoming more interconnected as sophistication increases across product portfolios. And the increase in market volatility means more demand for agility and adaptability.

Here, Jean-Baptiste Clouard, CEO at Flowlity, shares four AI supply chain challenges businesses face and how they can tackle them.

Challenge One: Data Restrictions

AI requires large amounts of precise data in order to work effectively, but a lot of businesses lack this in terms of quality and quantity. In order to train algorithms and prediction models, machine learning needs excellent data.

Data constraints should be minimised before AI is introduced into the supply chain so that it is easily accessible and integrates as much ‘real-time’ data as possible into processes and systems.

Corporations need to improve the quality of their data by implementing good data management and integrating real-time data wherever possible into processes and systems. When a continuous syncing of data occurs, it means that digital business networks can maintain a “single version of the truth” and ensure that businesses operate on the most available information.

When the most current data can be accessed, meaningful analysis and actionable insights can occur.

Challenge Two: Lack of trust in the technology

Artificial intelligence is still a relatively new technology which is still driving investment from innovators across the industry. However, it does mean that there are still hesitations from businesses and from people to use them.

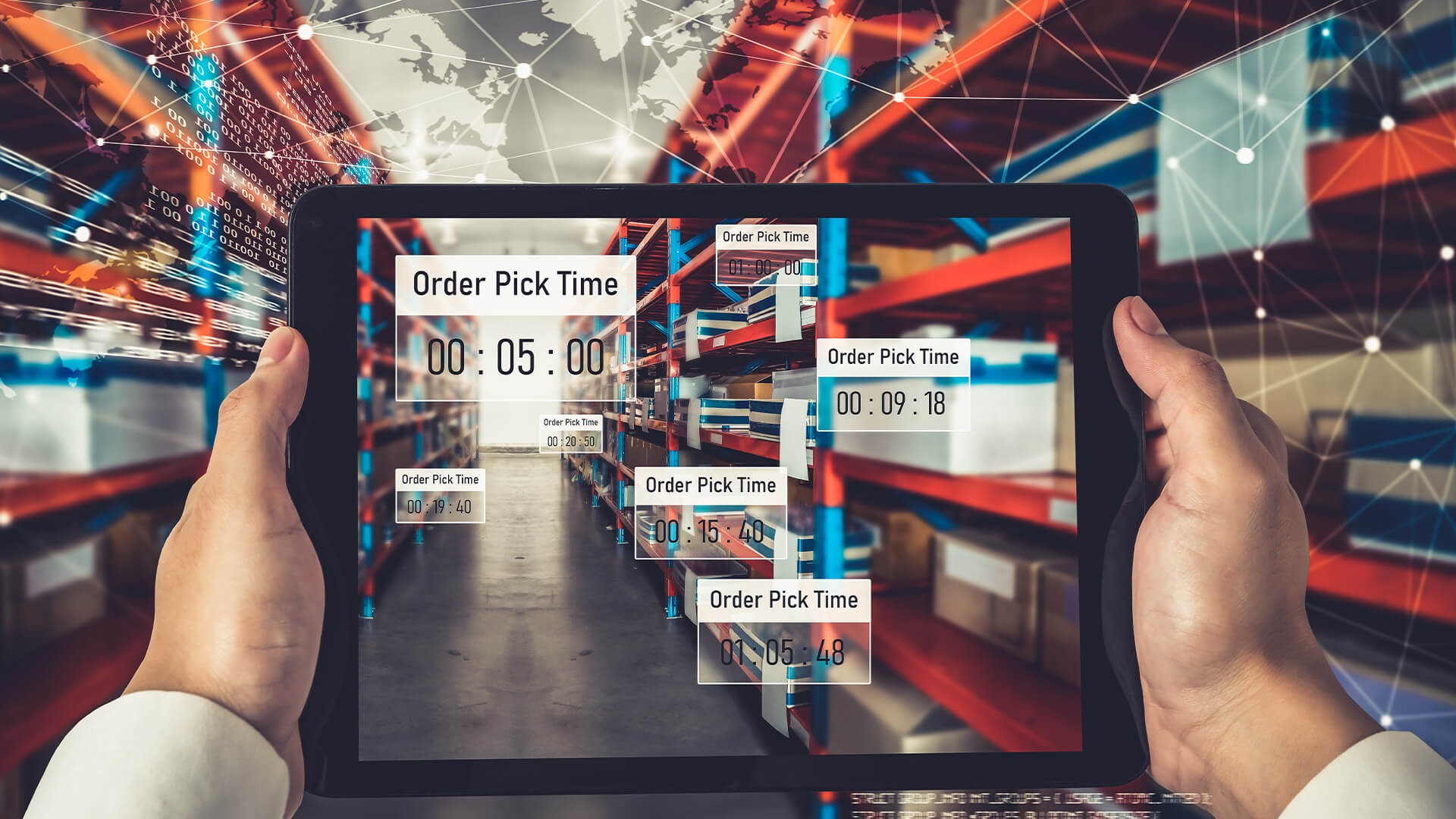

Implementing new systems, such as in warehouses, can mean moving from real people with years of experience to a computer system that seemingly doesn’t have the same skill set.

Humans are resistant to change but using AI systems across the supply chain can make significant improvements. They help improve and streamline planning processes and provide real cost and time-saving measures.

Combining data, algorithms and new processes with practised human expertise is complex and people often need to see it in practice to trust the abilities of AI. This is where a system like Flowlity can come in. It has been created by a team of experts in their field to create the best system possible.

Without this trust and the context of how AI can transform the supply chain – businesses won’t adopt the technology.

Challenge Three: technology constraints

As impressive as AI is, it still has some barriers and restrictions that it hasn’t quite yet overcome in terms of the technology itself. In fast-moving production businesses, decisions need to be made within moments – which is where a solution that combines real-world factors/predictions can benefit businesses.

With cloud-based AI systems, they need a large amount of bandwidth to power them. Businesses and operators might also need specialised hardware to access the AI capabilities and this can come with an associated cost.

Businesses need a solution where they can manage stock levels and procurement more efficiently so that it automates the planning and will send alerts to any potential issues.

Challenge Four: Operational costs

The cost of introducing AI into supply chain processes can be a challenge most businesses face. The initial upfront cost in terms of investing and integrating the technology can be expensive, but so can the operating costs. But choosing a SAAS solution can be more cost-effective than developing in-house solutions. AI is designed to make human work easier – by automating manual tasks or supporting a better decision-making process.

AI machines have complicated processes that require regular maintenance and even replacement. That said, with the right solution that is correctly optimised, over time it will prove cost-effective and will save businesses money by optimising inventories, planning and forecasting.

A sustainable supply chain is not a new concept but is still evolving for retailers and manufacturers. By overcoming AI challenges, businesses can implement a cost-effective solution that will streamline the supply chain for businesses.